Kaufman & Robinson offers a complete product line of radio frequency, inductively coupled plasma (RFICP) gridded ion source products. The RFICP’s can be configured and integrated into numerous vacuum process platforms, including bell jar systems, small multi-purpose R&D systems, planetary deposition systems, etching systems, box coaters, single wafer load-lock cluster tools, sputtering systems, and in-line coating systems.

The RFICP products come in a comprehensive product package. The package is complete with components required to install and operate the RFICP products, including the RF inductively coupled RFICP ion source, application-specific ion optics, electron source neutralizer, power supply controller, vacuum feedthroughs, and cables.

Our RFICP products are used across the globe in world class research and industrial fabrication of optical, photonic, magnetic, and microelectronic devices. The RFICP products are applied in standard and emerging material processes.

The ability to produce and control ion species with specific energy, chemical reactivity, current density, and ion trajectory makes the RFICP products effective tools to engineer precision films and surfaces. Whether it’s densification, optical transmission, critical thickness uniformity, smooth interfaces, improved adhesion, or vertical sidewalls, the RFICP products are responsible for yielding beneficial material properties.

Commonly, the RFICP products are applied in the following vacuum processes

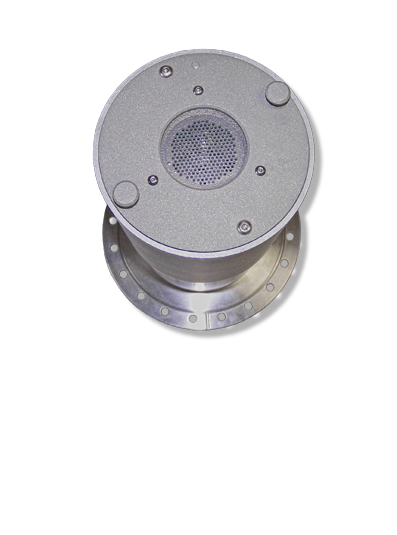

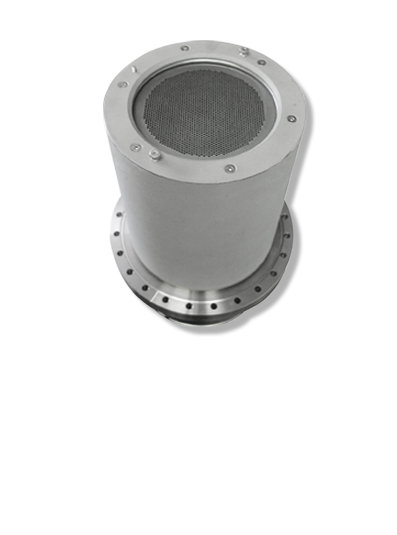

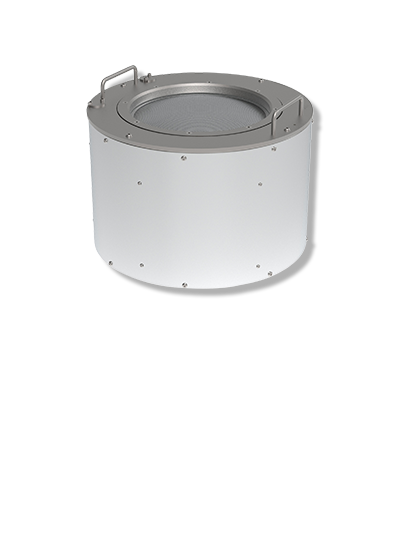

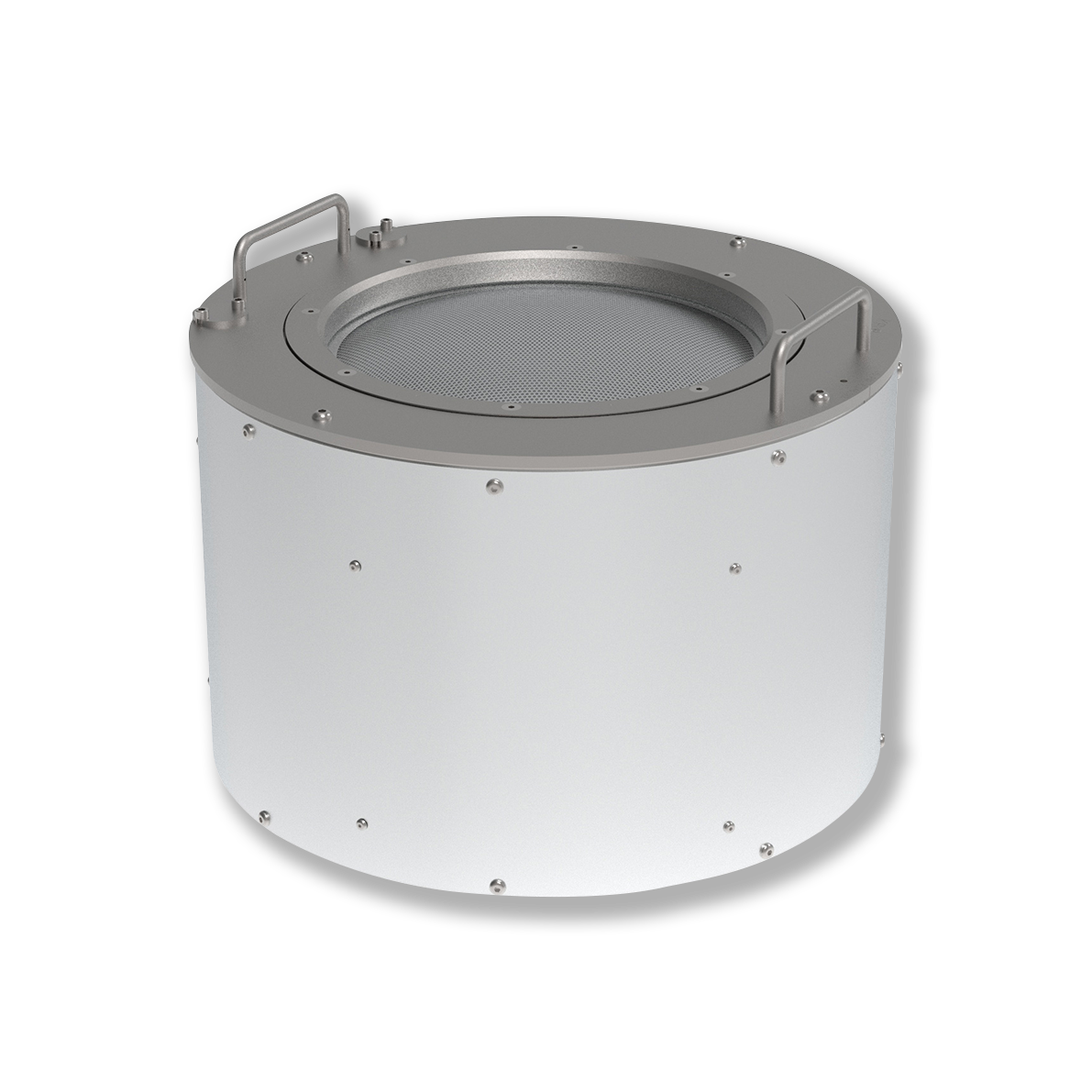

Our Gridded RFICP Sources

Contact Us

If you have questions about any of our products or their applications, please contact us. We look forward to hearing from you.