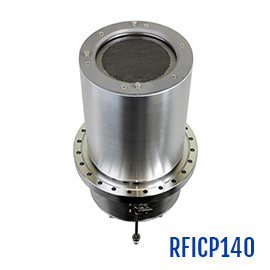

Kaufman & Robinson offers a complete product line of radio frequency, inductive coupled plasma (RFICP) gridded ion source products. The RFICP products incorporate our most innovative gridded source technology. Advancements such as the RF filament-less plasma discharge and self-aligned ion optics are proven benefits. Without a filament in the plasma discharge chamber, the RFICP products are suited to operation where reactive gas discharges and long process runs are critical.

The RFICP products come in a comprehensive product package. The package is complete with components required to install and operate the RFICP products, including the RF inductively coupled RFICP ion source, application-specific ion optics, electron source neutralizer, power supply controller, vacuum feedthroughs, and cables.

Our RFICP products are used across the globe in world class research and industrial fabrication of optical, photonic, magnetic, and microelectronic devices. The RFICP packages are configurable to suit installation platforms. These configurations can be integrated into numerous vacuum process platforms, including small multi-purpose R&D systems, dedicated planetary motion deposition or etching systems, box coaters, single wafer load-lock cluster tools, and low profile sputtering systems coaters.

The RFICP products are applied in standard and emerging material processes. The ability to produce and control ion species with specific energy, chemical reactivity, current density, and trajectory makes the RFICP products effective tools to engineer precision films and surfaces. Whether it's densification, optical transmission, critical thickness uniformity, smooth interfaces, improved adhesion, or vertical sidewalls, the RFICP products are responsible for yielding beneficial material properties. Commonly, the RFICP products are applied in the following vacuum processes:

- Ion beam assisted deposition in thermal and e-beam evaporation (IBAD)

- In-situ preclean in sputtering and evaporation (PC)

- Surface modification and activation (SM)

- Direct deposition of thin, hard, or functional coatings (DD)

- Ion beam sputter deposition of single and multilayer structures (IBSD)

- Ion beam etching of surface features in any material (IBE)

- Ion beam trimming, tuning, and figuring of precision devices (IBE)